COMPUTATIONAL FLUID DYNAMICS

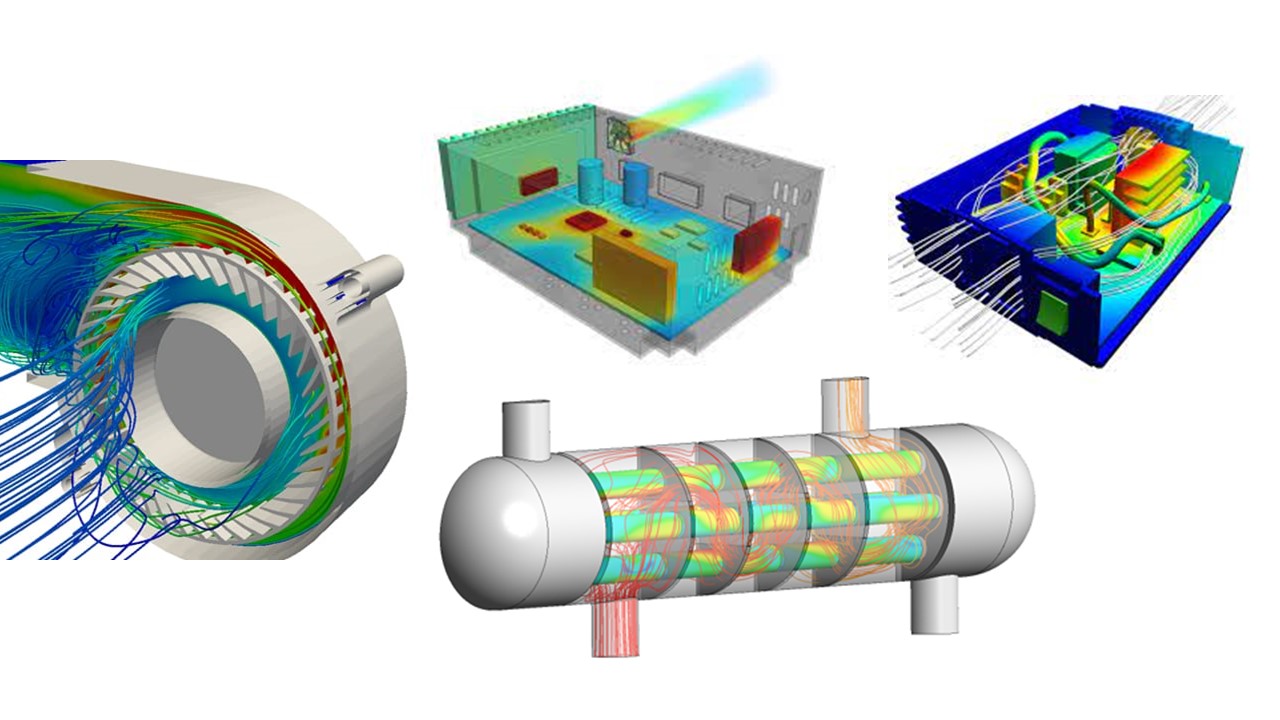

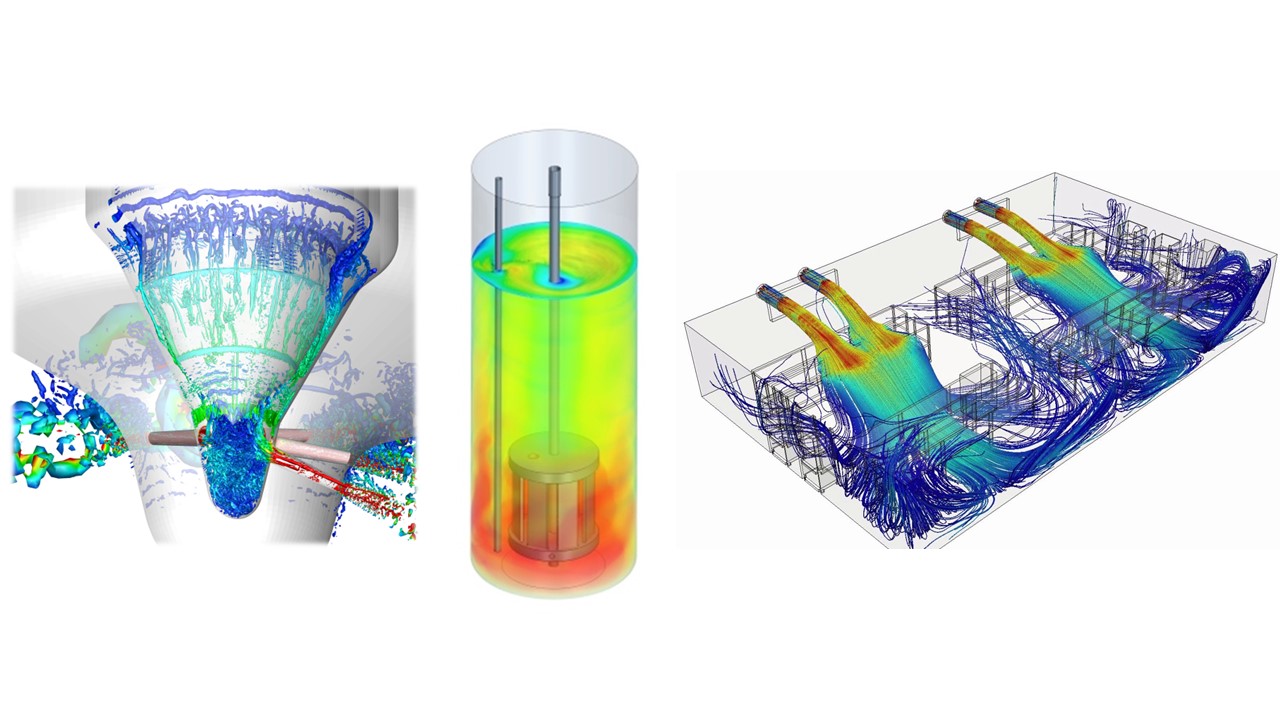

Our work with CFDUsing CFD, we analyze complex problems involving fluid-fluid, fluid-solid, or fluid-gas interaction.

In a CFD analysis, the desired quantities of fluid can be measured at once, with a high resolution

in space and time.

We use CFD simulations to study the airflow of an aerodynamic aircraft design or to examine a

product’s hydrodynamic properties.

A CFD simulation is the best way to validate fluid design conditions, examine

the fluid in a product at different conditions, and predict fluid behavior in terms of pressure,

temperature, flow distribution, and velocity.

We at GVPL Technologies can virtually analyze a product based

on the following flow conditions

• Fluid Pressure Drop

• Velocity Measurement

• Temperature Measurement of Fluid and Solid

• Heat Transfer

• Particle/ Impurity trajectory in fluids

• Phase change behavior

• Separation of fluids

• Mixing of fluids

• Flow and Distribution

With the help of different types of CFD, we have managed to assist several clients by analyzing

their

products. Here is a brief overview of our work with CFD over the years:

Flow analysis of valve

• Flow analysis of pump and turbine

• Flow analysis of dynamic mixer

• Pollution

control

in building

• Flow and thermal analysis of cabin

• Combustion in a furnace

• Thermal

analysis of economizer

• Particle separation in a cyclone separator

• Thermal analysis of

battery pack

• Thermal analysis of DG set

• Condensation in Headlamp

• Thermal analysis

of LED Fitting