REVERSE ENGINEERING

Our Expertise with Reverse EngineeringWith the help of our services like CAD, reverse engineering has made it possible to create 3D virtual

models of the existing part of machines in other software. Rendering such 3D models helps the

engineers examine the

design more closely, and later make changes in the design to make it more feasible.

We at

GVPL Technologies, use reverse engineering to optimize the physical geography of a design, in order

to develop a

product as well as its environment. It also helps us in establishing a digital 3D record of our

client’s designs and also provides an accurate assessment of our competitors’ products. This tech

also helps in analyzing

how a product works, and with it, its components estimated cost of manufacturing, and its potential

demand in the market.

In the process of product development and design, we use Reverse Engineering for

the following:

• Improving a product

• Correctly capturing the intent of the design

• Recording

data in a reliable manner

• Refining features of products

• Surface analysis of a product

design

• Updating older versions of a product with newer versions

• Improving the

performance of a product

• Reducing manufacturing costs

We use the following steps to deliver complete Reverse Engineering Solutions to our clients’

products:

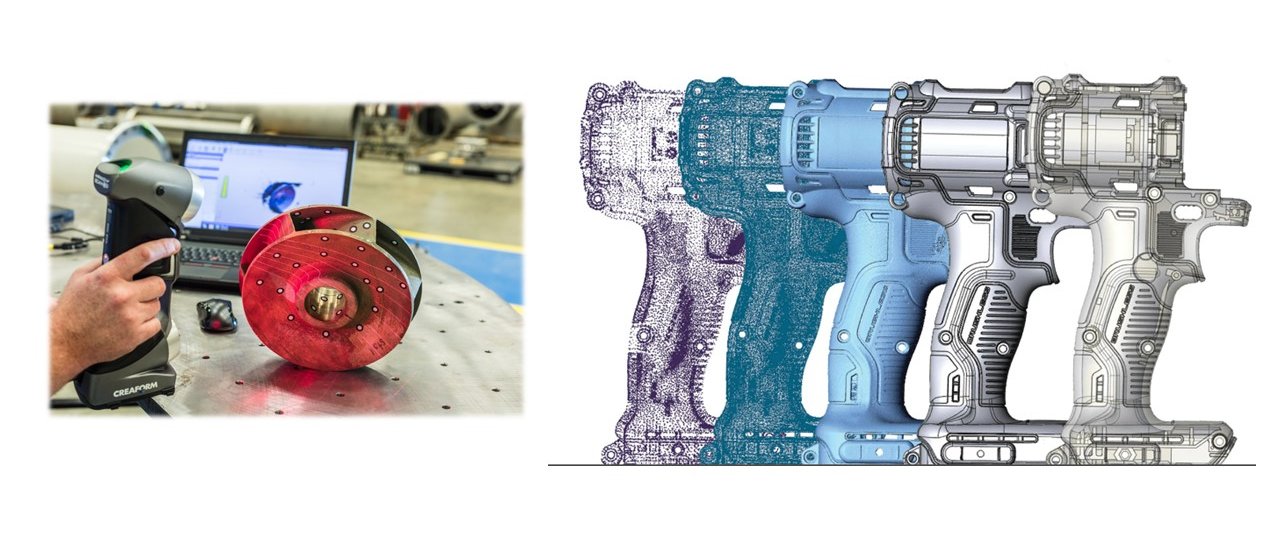

• Digitizing and Scanning : This method uses a Laser Scanning system to digitally

represent a product.

The data obtained is used to define or analyze complex geometry.

• 3D CAD Solid and

Modelling : We use this tech for rebuilding a product without violating dimensions to refine

the scanned model. We use

it for geometry visualization, drawings, complex tool paths and analysis.

• Engineering

Drawings : In addition to our other services, we also provide engineering drawings according

to the stringent requirements

of our clients. We also aid in conversion of old paper drawings to a CAD format.